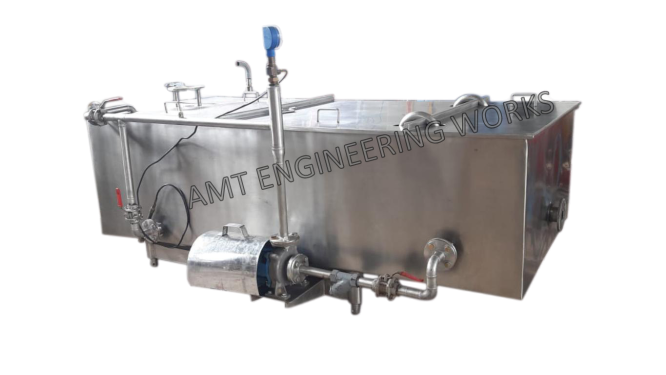

DUMP TANK

A dump tank is a vessel with a rectangular cross-section and an open top surface. It is work as a balance tank for milk in between the weigh bowl and milk chiller. Mostly it is used in dairy industries doing continuous milk processing. Milk first poured in weigh bowl and from it, it passes to this dump tank and further to the required processing section. Reckoned for sturdy and hygienic structure, these dump tanks are able to store the voluminous amount of liquid. They are either used in connection with the conveying system or individually where only small chilling center or bulk milk cooling center in villages are situated. It has an outlet at the flat bottom having a slop from three sides for easy draining of the liquid. Mounted on adjustable ball feet.

Weigh Bowl

We construct weigh bowls using finest quality stainless steel that is corrosion free. Our product comprises of the bowl with an outlet and closing valve. The unit has slope towards the outlet for the easy drain of the milk. Further, this valve possesses rubber o-ring for leakproof closing. We also offer these bowls as per the specifications of our clients.

Our bowls are Easy in operation and Quick response in time.They are contructed by using finest stainless steel. Theay are heavy duty machenical structure and high precision load cell.Bowls have excelent accurecy and speed and they are robust built.

Storage Tanks

AMT Engineering Works is a leading and well known manufacturer of Storage tank and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. We provide the best quality storage tanks that cool and maintain the milk quality at 40 C. After the extraction of milk at 370 C and continues to remain at the room temperature but this room temperature and bacterial growth will affect the quality of milk. These storage tanks cool the milk to 40 C in the specific time. These tanks are available in the different shapes and sizes depending on the amount of milk.

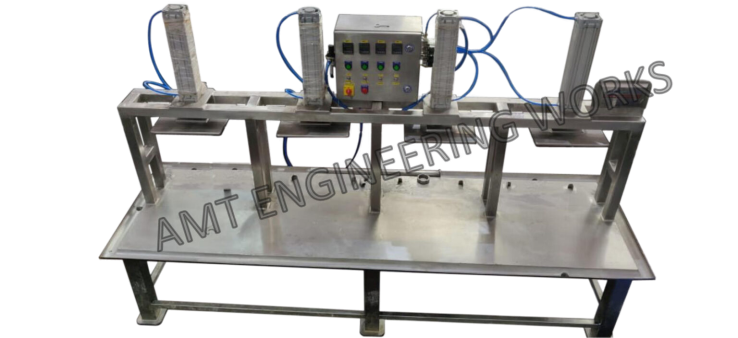

Can Scrubber

AMT Engineering Works is a leading and well known manufacturer of Can Washer and complete milk plants and dairy plants. Can washers are very well in demand by different names like Can scrubber, Milk Can Cleaner, Milk Can Cleaning Machine etc. Milk can scrubber machine is specially designed for the cleaning of milk cans from inside and outside. Our supplied milk can scrubber machine is highly acclaimed by the clients for rugged construction and easy operation.Standard 40 Litre Milk cans of 325 mm Body dia x 200 mm neck dia x 600 mm height can be washed.Robust fabricated 2 mm thick stainless steel confirming to AISI 430 with Rigid formed top edgeHolds a capacity 425 Liters approx in a bath space.1 hp, 1440 rpm, 3phase. TEFC degree of protection IP 55 electric motor

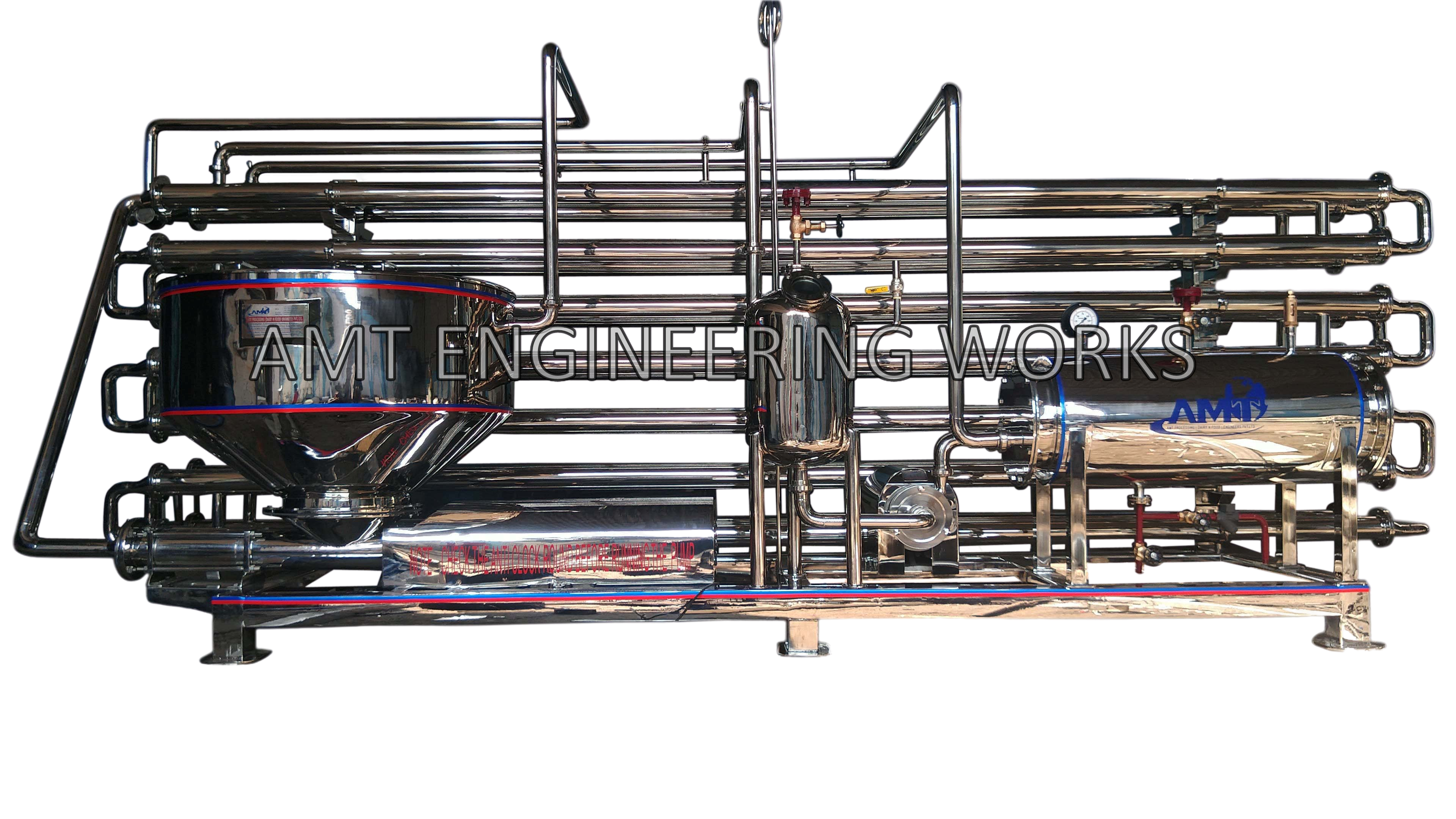

Milk Pasteurizer

AMT Engineering Works is a leading and well known manufacturer of Milk Pasteurizer and complete milk plants and dairy plants. Milk pasteurizer is able to eliminate those pathogenic bacteria harmful to our health, and preserve milk quality as much as possible. Our Milk pasteurizer plant is precisely using the quality machines with tested components and modern technology with international quality standards. This Pasteurizer Plant is available with technical Features.

Its performance is superior

Construction is very good

Finish standards

Balance Tanks

AMT Engineering Works is a leading and well known manufacturer of Balance Tanks and complete milk plants and dairy plants. A balance tank is a vessel that keeps product at a constant level above a pump inlet. The primary purpose of a balance tank is to keep the pump NPSHA constant. A balance tank will generally have a level sensor to help maintain tank volume. The balance tank also prevents air from entering the pasteurizer by placing the top of the outlet pipe lower than the lowest point in the tank and creating downward slopes of at least 2%. The balance tank provides a means for recirculation of diverted or pasteurized milk.

Milk Pump,Cream Pump

The sanitary and cost-efficient design of the stainless steel centrifugal pump for milk makes it particularly suitable as main process pump at milk production plants.

HYGINOX SE is a high quality dairy milk pump. This stainless steel centrifugal pump is commonly used as sanitary dairy milk pump in numerous milk processing applications.

This food-grade milk pump on cart is a typical milk industry pump characterised by gentle transfer of milk products.

Thanks to its smooth pumping, this standard centrifugal pump is used as typical milk transfer pump.

INOXPA offers milk pumping systems characterised by efficient pumping performance.

This stainless steel pump for milk is designed for stationary and mobile (centrifugal milk pump with cart) use in milk processing.

We believe in building relations with our clients by providing them utmost satisfaction with regard to our products. We

also maintain sound relations with our vendors as they form a part of the quality of goods we supply.

Our mission is to provide high quality service/ product combined with trusted client partnership, and to maintain high

health and safety levels and solutions to the client’s need.

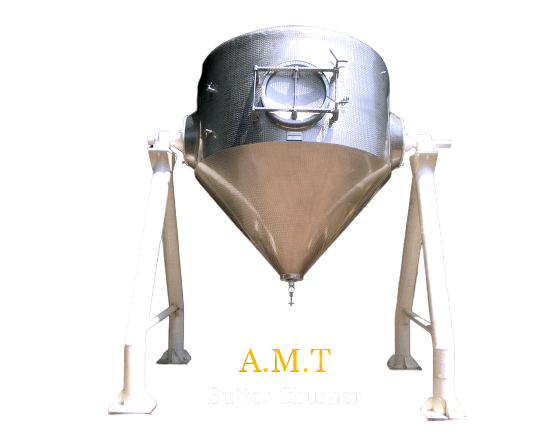

Butter Churner

AMT Engineering Works is a leading and well known manufacturer of Butter Churner and complete milk plants and dairy plants. A butter churner is used to convert cream into butter. This is done through a mechanical process, frequently via a pole inserted through the lid of the churn, or via a crank used to turn a rotating device inside the churner.

Doors Leak - proof hinged Door of size 350 x 350 mm clear opening with proper locking arrangement in both open & closed position and made from SS 316 / 4 mm. thk. sheet and provided with ‘U‘ type nitrile gasket of dairy standard.

Sight glass Dia 130 x 12 mm.thk. Flange SS 316 ,toughened glass

Drain cock Dia. 25 mm drain cock used for butter milk drain

Air release cock Dia. 25 mm, To release the air from the churn barrel

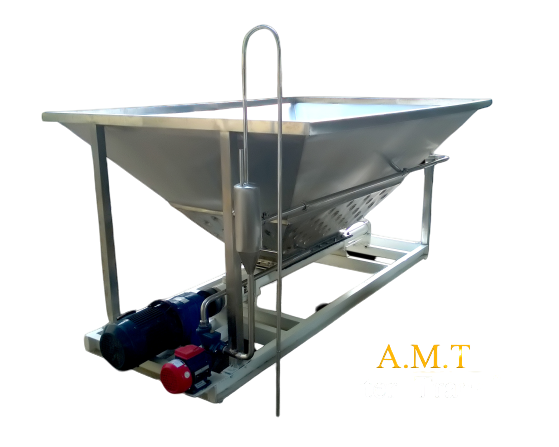

Butter Transfer System

Established in 1983, AMT Engineering Works are one of the leading manufacturers and exporters of a complete “Design,

Manufacture, AMT Engineering Works is a leading and well known manufacturer of Butter Transfer System and complete milk plants and dairy plants. Butter Transfer System used for transfer butter for further process and It placed at the bottom of butter churner. The Hot water jacketed helps butter to melt and formed into vessel. The screw in the bottom transfer it for further process.

This machine butter to a place of relocated able to carry packing to comfortable and butter melting to all the machine

Butter Melting System

AMT Engineering Works is a leading and well known manufacturer of Butter Melting System and complete milk plants and dairy plants. These melting systems are widely used for melting products like products made from vegetable fats, margarine, AMF and butter

Combination of melting grid and storage tank with stirrer

Removable melting grid makes it easy to clean inside the tank.

The melting grid is made of quadrangular, stainless steel tubes and is heated with hot water up to 90°C.

The machine is made of stainless steel and cover is detachable from the top of the tank for cleaning purposes.

Mixing element at the bottom to optimise melting at the storage section below the grid

Roller Conveyor

Roller Conveyors use parallel rollers mounted in frames to convey product. They may be powered by gravity, a motor or manually. Key specifications include the roller diameter and axle center dimensions.

Roller conveyors are used primarily in material handling applications such as on loading docks, for baggage handling, packaging, or on assembly lines among many others.

The rollers can use gravity, if inclined, to move the product, or manually if mounted horizontally. The conveyors can be straight or curved depending on the application and available floor space. The rollers can also be powered to convey the material.

We believe in building relations with our clients by providing them utmost satisfaction with regard to our products. We

also maintain sound relations with our vendors as they form a part of the quality of goods we supply.

Our mission is to provide high quality service/ product combined with trusted client partnership, and to maintain high

health and safety levels and solutions to the client’s need.

Crate Washer

The crate washers are made of stainless steel and have a hygienic design thanks to HACCP standardization. The Washing systems are adapted to the good to be cleaned. Thanks to an integrated water filter, the crate washeris extremely resource-saving when cleaning boxes and boxes.

We believe in building relations with our clients by providing them utmost satisfaction with regard to our products. We

also maintain sound relations with our vendors as they form a part of the quality of goods we supply.

Our mission is to provide high quality service/ product combined with trusted client partnership, and to maintain high

health and safety levels and solutions to the client’s need.

Ghee Kettle

AMT Engineering Works is a leading and well known manufacturer of Ghee Kettle (Ghee Boiler) and complete milk plants and dairy plants. The Ghee Boiler that we supply in the market is widely used in dairies for separating the ghee from cheese and in various industries for food processing applications. These ghee boiler are very effectual for the bulk boiling of a large amount of ghee at the same time. These are offered in customized capacity according to the requirement of the clients.

Features:

Flawless finish

Ensures optimal performance

Tough construction

Ghee Settling Tank

AMT Engineering Works is a leading and well known manufacturer of ghee settling tank and complete milk plants and dairy plants. Our provided Ghee Settling Tank find its extensive usefulness in food processing fields and dairy farms. After melting, separation, clarification and filtration operations, this tank is specially used to store ghee ready to pack before the final dispatch. This tank stores ghee safely due to its excellent thermal and mechanical stress enduring property. Mounted on heavy duty legs, this tank prevents the chances of temperature loss as it is perfectly fabricated from all sides. This tank is manufactured using stainless steel and cutting-edge technologies. You can get this Ghee Settling Tank in several standard sizes, capacities, configurations, etc.

Paneer Vat ( Cheese Vat )

AMT Engineering Works is a leading and well known manufacturer of insulated and uninsulated rectangular tanks with partition plates used as Paneer Chilling Vat and complete milk plants and dairy plants. The chilled water is circulated to cool the paneer. Additional skid mounted system to generate chilled water is also provided along with the paneer vat.

Provided machine is known for its user-friendly operation and less noisy functionality. Offered machine is available in different specifications as per clients requirements. This machine is manufactured under observation of our dexterous professionals at modern production unit with latest innovative techniques.

Paneer Press ( Cheese Press )

AMT Engineering Works is a leading and well known manufacturer of Paneer Press (Cheese Press) and complete milk plants and dairy plants. These machines are widely used in dairies for making cheese due to its exceptional functional life and high operational fluency. This Cheese Press Machine is manufactured using the superior quality components and cutting edge techniques by our experienced professionals. These are available in various production capacities, sizes, weights and models as per clients.

various features like:

High reliability

Sturdiness

Long life

Précised dimensions

Resistant to abrasion

High performance

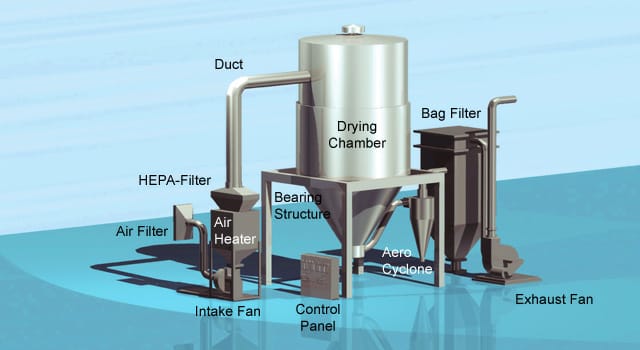

Evaporator Unit

AMT Engineering Works is a leading and well known manufacturer of falling film evaporator and complete milk plants and dairy plants. The falling film evaporators have many advantages over submerged tubes evaporators. In the past, the vertical tubes evaporators were considered as most efficient but now they have been replaced by falling film evaporators due to its distinctive nature of operation. Our falling film evaporator is specifically suited to process your products with a low viscosity and a low tendency for fouling. It consists of a tube bundle crowned by a proprietary liquid distribution device that ensures an efficient and uniform distribution of the liquid to all the tubes. Your product flows as a continuous film along the tube length, driven by gravity.Usually the liquid and the vapors formed flow co-currently from the top to the bottom and are separated in a gas-liquid separator installed at the end of the tube bundle.

Concentrate Tank

Concentrated and Dried Dairy Products. Fluid milk contains approximately 88% water. Concentrated milk products are obtained through partial water removal. The benefits of both these processes include an increased shelf-life, convenience, product flexibility, decreased transportation costs, and storage.

We believe in building relations with our clients by providing them utmost satisfaction with regard to our products. We

also maintain sound relations with our vendors as they form a part of the quality of goods we supply.

Our mission is to provide high quality service/ product combined with trusted client partnership, and to maintain high

health and safety levels and solutions to the client’s need.

Khoa Kettle

AMT Engineering Works is a leading and well known manufacturer of Steam Jacketed Kettle and complete milk plants and dairy plants. The primary machine of a food processing industry is also called cooking kettle. It has double jacket on app. 70 % portion thro’ which steam is passed. The kettle is connected to the boiler by steam line it has safety valve, pressure gauge and pet cock in the bottom to release condensed water or extra steam.

Highlights :

. Longer service life

. Environment friendly

. No heat to the surroundings and operators

. Re-use of condensate water

. Only one operator is required in three sets of kettles

. Hassle free operation

Homogenizer

We offer to our clients wide range of HomogenizerDairy Equipment which have a heavy application in dairy industries. Available for heating, melting, homogenizing and emulsifying materials, it is ideal device for paste-cream products of middle and high grades. This equipment includes oil phase boiler, water phase vessels, emulsification vessels, operation platform and control tank.

We believe in building relations with our clients by providing them utmost satisfaction with regard to our products. We

also maintain sound relations with our vendors as they form a part of the quality of goods we supply.

Our mission is to provide high quality service/ product combined with trusted client partnership, and to maintain high

health and safety levels and solutions to the client’s need.

Powder Venturi

AMT ENGINEERING WORKS is the leading manufacturer of Powder Venturi (Powder and Liquid Mixer ) and complete milk plants and dairy plants and milk plants and dairy plants equipments manufacturers in India. Powder Mixer Venturi Machine (Powder and Liquid Mixer ) used for mixing powder and liquid properly. Powder Venturi (Powder and Liquid Mixer ) mostly used in milk powder plants, food processing plants and Dairy products plants.

We believe in building relations with our clients by providing them utmost satisfaction with regard to our products. We

also maintain sound relations with our vendors as they form a part of the quality of goods we supply.

Our mission is to provide high quality service/ product combined with trusted client partnership, and to maintain high

health and safety levels and solutions to the client’s need.

Inoculation Tank

Dahi Inoculation Tank. In this tank,the milk at 42 degree is mixed with dahi culture so that dahi is formed. Firstly,hot water flows which maintains the temp.at 42 degree celcius. The outer jacket has insulation to prevent heat loss. The tank is provided with slow speed agitator for steady mixing of milk and culture.

We believe in building relations with our clients by providing them utmost satisfaction with regard to our products. We

also maintain sound relations with our vendors as they form a part of the quality of goods we supply.

Our mission is to provide high quality service/ product combined with trusted client partnership, and to maintain high

health and safety levels and solutions to the client’s need.

Steam Jacketed Kettle

Jacket and pan made of 10/10 high tight swg. Stainless steel SS 304.

Complete with pressure gauge, safety valve, and steam pet cock. The steam trap can be supplied at an extra cost.

The kettles are 2/3 jacketed for maximum steam utilization and efficiency.

Kettle bottom with hemispherical design for heat transfer.

Mounted on a mild Steel Stand / Stainless Steel Stand.

The kettle has a tilting arrangement through worm gear/pinion which helps to completely empty the contents from it.

The temperature shall be completely uniform throughout the entire jacketed surface of the kettle to eliminate any hot spots to scorch the pan or product.

Jelly Tank

Established in 1983, AMT Engineering Works are one of the leading manufacturers and exporters of a complete “Design,

Manufacture, Supply, Erection & Commissioning of Food Processing Engineering Machinery/Projects. Our efforts

towards maintaining superior quality in our services helps us in bringing further enhancements in our range, designing

and developing them to meet the specific standard and customized needs of our global clients. Our range includes Raw

Milk Processing Equipment, Ghee, Butter and Curd Processing Machinery. We have complete range of machineries of

all units of milk processing and milk products plant

We believe in building relations with our clients by providing them utmost satisfaction with regard to our products. We

also maintain sound relations with our vendors as they form a part of the quality of goods we supply.

Our mission is to provide high quality service/ product combined with trusted client partnership, and to maintain high

health and safety levels and solutions to the client’s need.

Khoa plant

Khoa is a partially dehydrated whole milk product prepared by desiccation of milk to 65-70 percent total solids in an open pan. Milk contains nearly 83-87 percent water; in order to increase the concentration of milk, water is evaporated from the milk by boiling. Khoa is used as a base material for the preparation of variety of sweets like burfi, peda etc.

We believe in building relations with our clients by providing them utmost satisfaction with regard to our products. We

also maintain sound relations with our vendors as they form a part of the quality of goods we supply.

Our mission is to provide high quality service/ product combined with trusted client partnership, and to maintain high

health and safety levels and solutions to the client’s need.

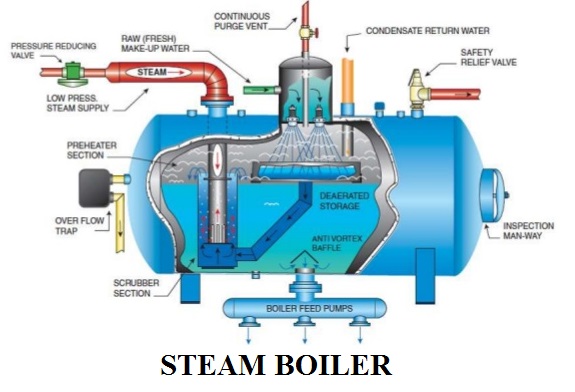

Steam Boiler

Generally, a steam boiler is a type of closed container, designed with steel for heating the water to generate steam by some energy source like burning of fuel with eventually. The vapor generated may be delivered at low-pressure for the industrial progression work in sugar industries, cotton mills, and for generating steaming water that can be utilized for heat up fixing at much low-force. The capacity of the boiler should have ten liters of water and the working pressure must be 3.4 Kgf/cm2 (kilogram-force).

A steam boiler is a power generation device, used for generating steam by applying the heat energy to water. The pressure range of earlier boilers ranges from low pressure to medium pressure (7 kPa to 2000 kPa/ 1psi to 290 psi). The present boilers are more useful because it works with high pressure than old ones. This boiler is very used whenever a steam source is necessary, and the size, type mainly depends on the type of application like mobile steam engines which includes handy engines, steam locomotives, and road vehicles.

Filters

Generally, a steam boiler is a type of closed container, designed with steel for heating the water to generate steam by some energy source like burning of fuel with eventually. The vapor generated may be delivered at low-pressure for the industrial progression work in sugar industries, cotton mills, and for generating steaming water that can be utilized for heat up fixing at much low-force. The capacity of the boiler should have ten liters of water and the working pressure must be 3.4 Kgf/cm2 (kilogram-force).

A steam boiler is a power generation device, used for generating steam by applying the heat energy to water. The pressure range of earlier boilers ranges from low pressure to medium pressure (7 kPa to 2000 kPa/ 1psi to 290 psi). The present boilers are more useful because it works with high pressure than old ones. This boiler is very used whenever a steam source is necessary, and the size, type mainly depends on the type of application like mobile steam engines which includes handy engines, steam locomotives, and road vehicles.