DISTILLATION VESSAL

Reaction vessels are used in carrying out a wide varity of chemical reaction including condensation,polymerization, esterfication,hyrolysis,hydration,reduction,oxidation,hydrogenation etc. at pressure s (up to 30kg/cm2) and at tempratures ranging -20°C to 250°C. Reaction needing simultaneous fractional distillation and azeotropic distillation can also be conducted very efficiently using these chemical reaction vessels.

DOUBLE CONE BLENDER

Double cone blender is vesry efficient for mixing dry powder and granules to manufacture products for different industries such as pharmaceutical,food,chemical,cosmetics,detergents,fertilizers,plastic etc. Our cone blender ensure proper mixing of powder & granules.We specially design our blenders in such a way that you could avoid the generation of dust from double cone blender.

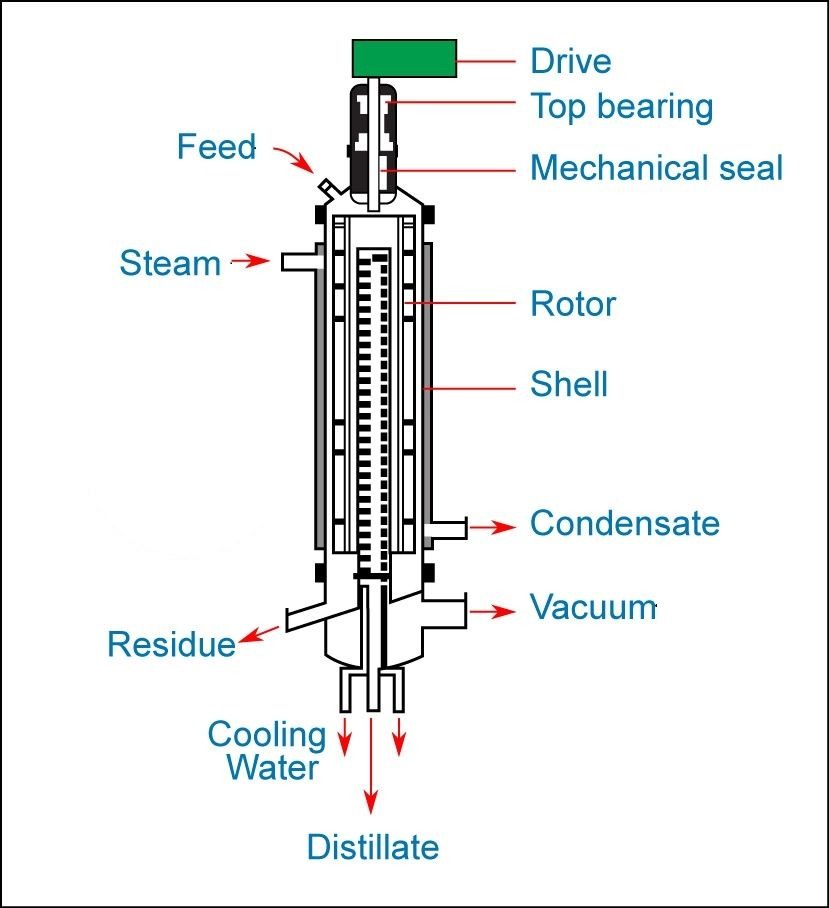

THIN FILM EVAPORATOR

The thin film evaporator is used for concentration, distilling,stripping,dehydration and deodorisation of products which are heat sensitive or viscous.the equipment can handle a very wide range of feed composition range from 1% to over 95% concentration .WFE has several advantage as stated in the table below The operation is continous with single pass;the self cleaning continuous contact wipers produce and renew the thin film such an operation improves product yield,avoids residue and colour formation .it has an internal condenser that minimizes thr pressure drop and maintains vaccum

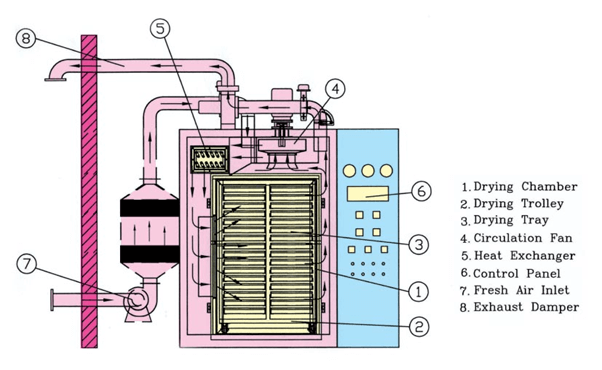

VACCUME TRAY DRYER

VTD is suitable for drying of thermal sensitive materials easily resolved,polymerized or deteriorated under higher temparature . Sterilization can be contucted prior to the drying process,during which no matters is allowed to enter the product .Static vaccume dryer elimimination damage of the drying materials ,there fore widely used in phrmaceutical,chemicals and foodstuff etc.

REACTION VESSELS

Reaction vessels are used in carrying out a wide variety of chemical reaction including condensation ,polymerization,esterification,etherification,hydrolysis,hydration ,reduction , oxidation, hydrogenation etc at pressure (up to 30kg/cm2) and at temprature ranging .Reaction needing simultaneous fractional distillation and azeotropic distillisation can also be conducted very efficientley using these chemical raction vessels

MATERIAL OF CONSTRUCTION:-

Vraious material of construction ,such as MS,SS04,SS316,SS3161,Rubber lined etc ,can be offered as per requirment

DESIGN:-

Standards chemical reaction gvessels and reaction kettle designed for 3kg /cm2 internal pressure or full vaccume ,jacketed vessels are designed for 3kg/cm2 jacket pressure or full vaccum.Heavy -duty vessels for higher operating prssures are also available as per process requirment for reaction vessels for highly inflammable material .Machenical seal with supporting assembly can be provided .Variable speed drives and flame proof motors can be incorporated for special application agitators.

STORAGE TANK

AMT Engineering Works is a leading and well known manufacturer of Storage tank and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. We deal S.S Storage Tank, which is applicable to various type of chemical industries and pharmaceutical industries for processing and storage of their products. It is also used to store milk.

TILTING PASTE KETTLE

AMT Engineering Works is a leading and well known manufacturer of Tilting Paste Kettle and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. The tilting paste kettle, is designed for paste preparation. It has a universal application resulting in uniform melting. This tank is designed to meet missing needs of wider range of products under varied operating conditions in Chemicals, Foods, Cosmetics and Pharmaceutical Industry.

PULVERIZER

AMT Engineering Works is a leading and well known manufacturer of Pulverizer and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. Materials from mill hopper into the pulverizing chamber to pulverize through The high-speed rotary blade, Adjust the distance between the classification round and the classification set to reach the required fineness of materials.

CENTRIFUGAL TRANSFER PUMP

AMT Engineering Works is a leading and well known manufacturer of Centrifugal Transfer Pump and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. Centrifugal pump is the most common pump used to transfer liquid in the wide range of applications which may range from food processing, pharmaceutical, cosmetic and many other industries.

MULTI MILL

AMT Engineering Works is a leading and well known manufacturer of Pulverizer and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. Materials from mill hopper into the pulverizing chamber to pulverize through The high-speed rotary blade, Adjust the distance between the classification round and the classification set to reach the required fineness of materials.

SCREW CONVEYOR

AMT Engineering Works is a leading and well known manufacturer of Screw conveyor and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. Screw Conveyor offers a variety of solutions for conveying or feeding a range of products such as raw materials, powdery and granular materials.

TABLET INSPECTION BELT

AMT Engineering Works is a leading and well known manufacturer of Tablet Inspection Belt and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. Tablet Inspection Machine is used for visual Inspection of Tablets, both coated and uncoated type of all sizes, most conveniently and at a very high speed, ensuring strict Quality control at the same time maintaining good checking rate. The speed of feeding of tablet can be regulated by electronic regulator. The tablets are inspected on one side and automatically get reversed and travel on lower belt for inspection on the other side of the tablet. The rejected tablets are removed by hand.

POWDER MASS MIXER

AMT Engineering Works is a leading and well known manufacturer of Powder Mass Mixer and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. Powder Mass Mixer mixing a assembly wherein the mixing stirrer is in horizontal position in the container & have a single speed, simple rotation. It is designed for uniformly mixing of dry and wet material and especially suitable for powder of Pharmaceuticals, Food, Herbals, Agro Chemicals & Chemicals.

FLUID BED DRYER

AMT Engineering Works is a leading and well known manufacturer of Fluid Bed Dryer and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. fluid bed dryer is a kind of equipment used extensively in the pharmaceutical industries to reduce the moisture content of pharmaceutical powder and granules.This is efficiently employed for applications in chemical, pharmaceutical, dyetuff, foodstuff, dairy and various other process industries. Fluid bed dryers are often employed with the spray dryers and granulation systems for effective drying, mixing, granualtion, finishing and cooling of powdered substances.

TABLET COATING PAN

AMT Engineering Works is a leading and well known manufacturer of Tablet Coating Pan and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. A tablet coating machine is an equipment that coats the external surface of a tablet using a thin coating material. Working principle of tablet coating machine is simple where the application of coating material is done on a moving bed of tablets and removing rapidly the solvent using a current of hot air.

PLANETARY MIXER

AMT Engineering Works is a leading and well known manufacturer of Planetary Mixer and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. The planetary mixer is so named because the mixing blade (commonly known as the beater) rotates in a planetary motion inside the mixer bowl. A planetary mixer can have different number, shape or size of blade which is mounted on its unique axis which are hanging above the mixing bowl. They are selected and can be designed as per the requirements.

RIBBON BLENDER

AMT Engineering Works is a leading and well known manufacturer of Ribbon Blender and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. Ribbon Blender is a light duty blender maily used for easy to mix powder components which are pre-processed like dried granules, pre-sieved powders etc. A ribbon blender consists of a U-shaped horizontal trough containing a double helical ribbon agitator that rotates within.

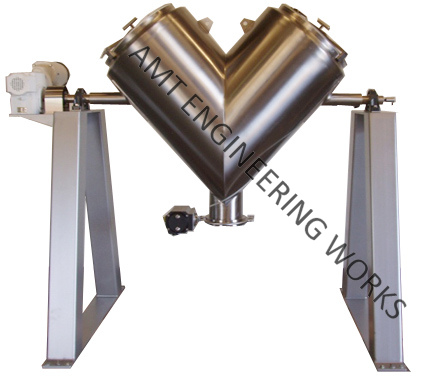

V-BLENDER

AMT Engineering Works is a leading and well known manufacturer of V-Type Blender and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. The V-BLENDER is an efficient and versatile blending machine for mixing and lubrication process of dry powders homogeneously. The solids being blended in these units can vary in bulk density and in percentage of the total mixture. Materials being blended are constantly being split and intermixed as the shell rotates.

RAPID MIXER GRANULATOR

AMT Engineering Works is a leading and well known manufacturer of Rapid Mixer Granulator and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. Rapid mixer granulator is widely used in Pharmaceutical plants. It is used to mix the pharmaceutical ingredients and make the granules before compression and also called a high shear mixer. Dry mixing is done by adding all ingredients into the RMG by rotation of impeller and chopper at high speed.

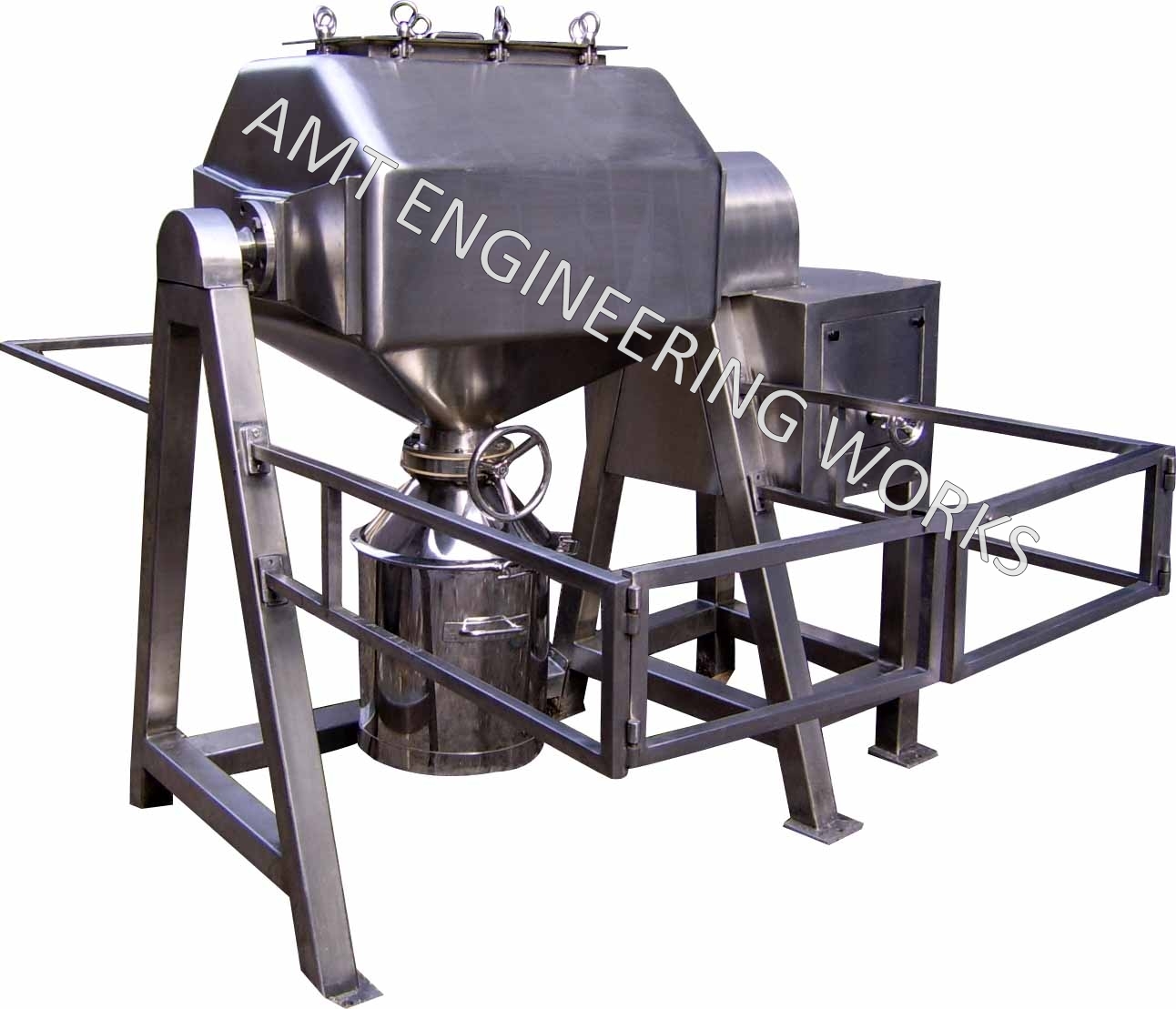

OCTAGONAL BLENDER

AMT Engineering Works is a leading and well known manufacturer of Octagonal Blender and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. Octagonal Blender, its octagonal shape is designed to process larger volume of material. It has been developed for mixing of various types of granular products. The machine is efficient and versatile used in mixing and lubrication processes in various industries. It is widely used in pharmaceutical production, food industries, chemical processing and also making of cosmetic products.

3 POINT CENTRIFUGE

AMT Engineering Works is a leading and well known manufacturer of 3 Point Centrifuge and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. 3 Point Centrifuge is used to separate the solid and liquid by the process of filtration. These machines have a hassle-free performance life and also have fast loading and unloading.

VIBRO SIFTER

AMT Engineering Works is a leading and well known manufacturer of Vibro Sifter and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. Vibro sifter is an essential accessory for the gradation of materials in many laboratory and industrial processes. It has a circular gyratory screen which separates mass composition of solids and liquids on the basis of their grades and particle sizes. The machine consists specially designed vibratory motor that generates vibration in three different planes along the vertical axis.

RECEIVERS

AMT Engineering Works is a leading and well known manufacturer of Stainless Steel Receivers and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. SS Receivers are used in industries to store solvents. These receivers are generally been used in industries like chemical, pharmaceutical, Herbal, food processing biotechnology etc.

.jpg)

NUTSCHE FILTERS ( NUTCH FILTER )

AMT Engineering Works is a leading and well known manufacturer of Nutsche Filters and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. Nutsche Filter is a closed vessel designed to separate solid and liquid by filtration under pressure or vacuum.

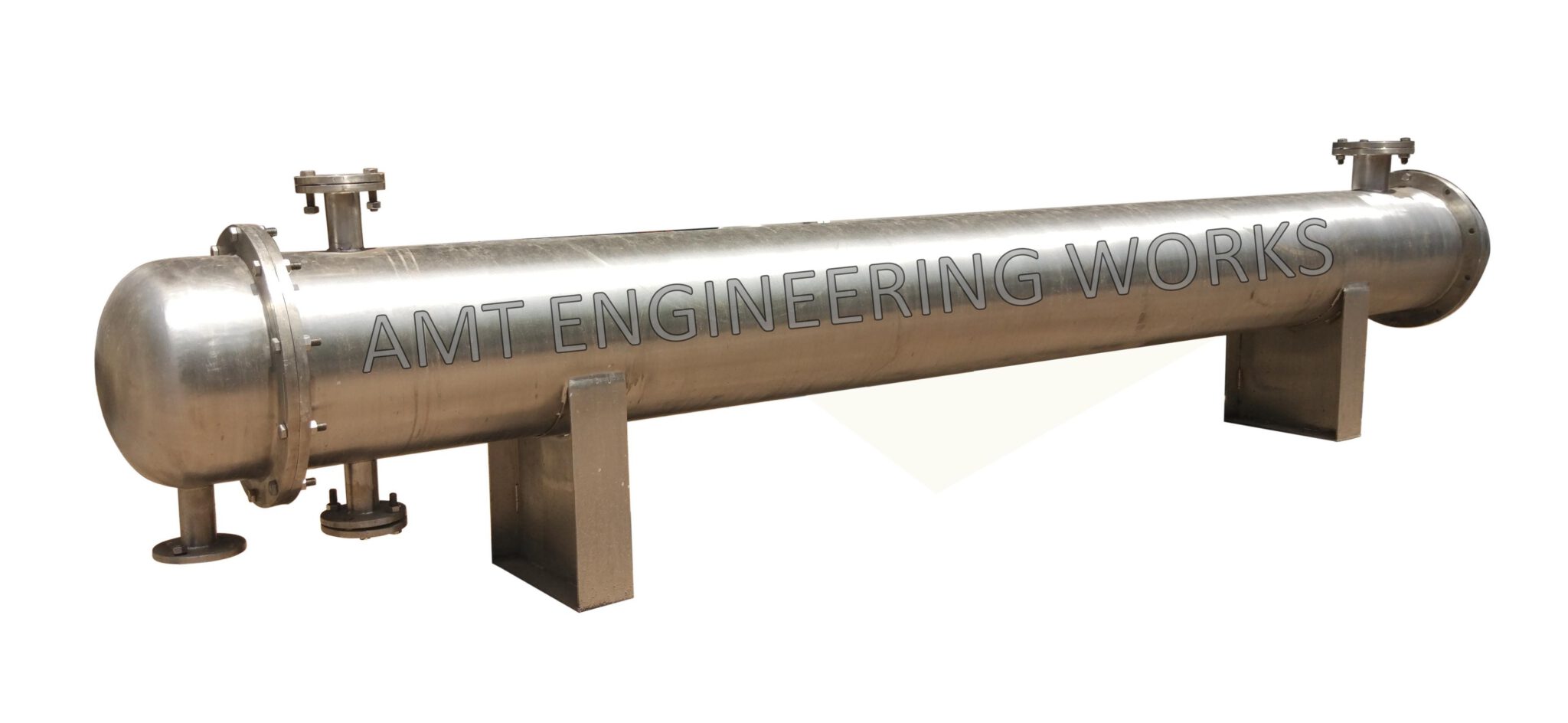

SHELL AND TUBE CONDENSER

AMT Engineering Works is a leading and well known manufacturer of Shell and Tube Condenser and complete Pharmaceutical Plants and Pharmaceutical Plant Machinery manufacturer in India. Shell-and-tube condensers are used to condense the exhaust steam exiting the turbine into condensate water which is recycled back to be turned into steam in the steam generator. It mainly works through condensing the vapors flow through tubes where they are treated with cooling water over external surface.